It all starts here. From piece of fabrics and thread reels to the best mattress covers, from reels of metal wire to orthopedic blocks of pocket springs of any sizes, from raw materials like coconut fibers to premium toppings of the most advanced mattresses. We take any idea you have, and deliver you the finalized product, whether it is a batch of compressed mattresses to your warehouse, or a roll packed mattress drop shipped right to your customer’s doorbell. Here, we do A to Z, without limits. Here, we do it all!

The cover

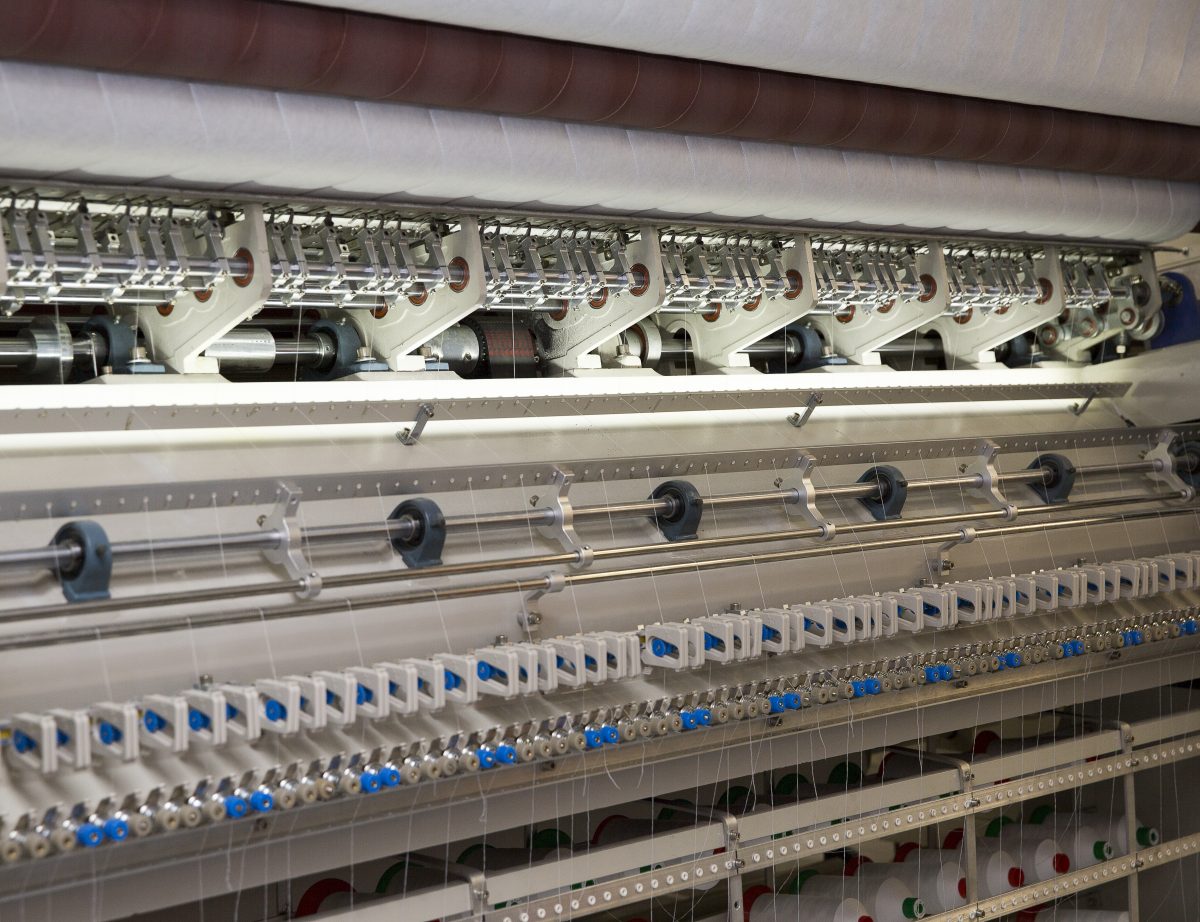

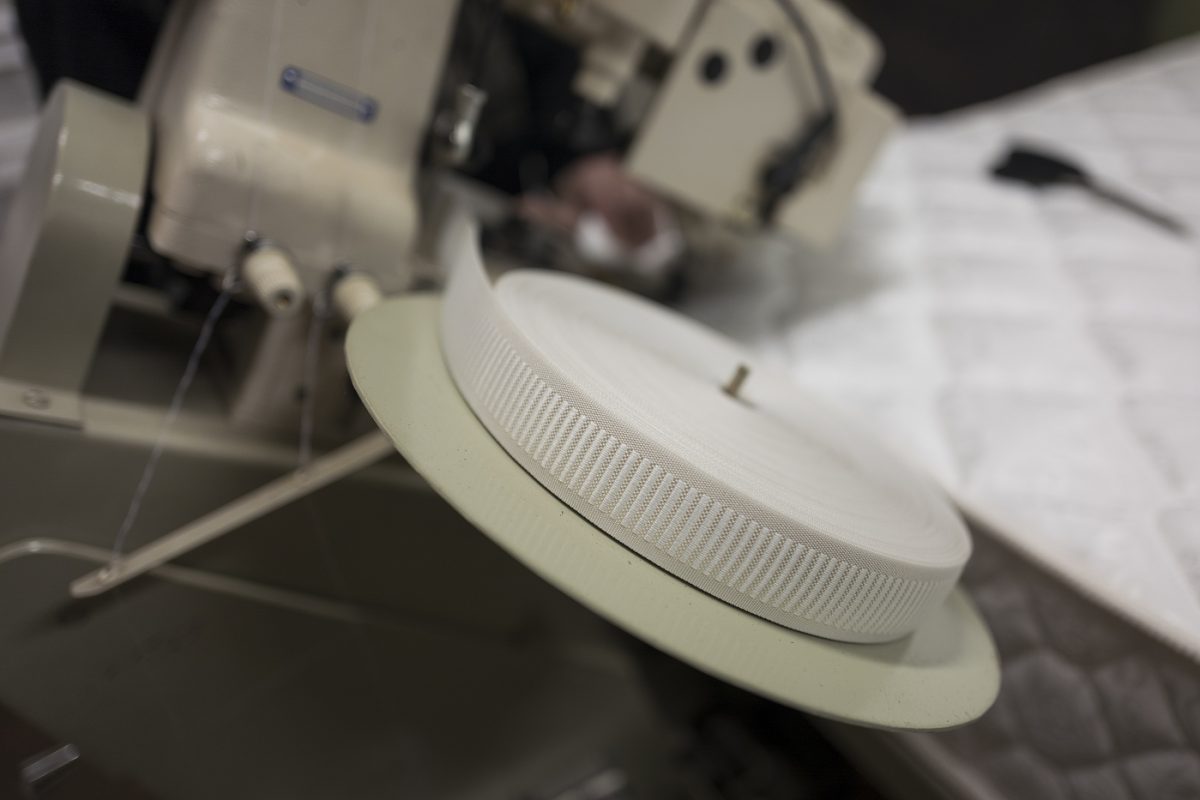

One of the main components of any mattress, and by far the most esthetic one is the cover. Being the “cover of the book” it should be both strong and durable to hold mattress in shape for years, as well as beautiful and nice to touch, as per customer’s standards. Consuming kilometers of various fabrics monthly, our factory has its own quilting subdivision. Such a complex in house machinery allows us to gradually increase fabrics processing speed, while decreasing production costs and what’s most important, allows us to customize quilting pattern of any part of a mattress cover on the go, per customer’s request.

As a wholesaler, we give our customers a number of options: first is going for our on the shelf available models, which can be found in “Mattresses” category of this website. Second is slightly modifying these existing models, by for example alternating quilting pattern, or embedding your own logo into a mattress. Third is creating your own brand new models, which can be done either from scratch through our collaboration, or using reverse engineering of your models, in that case you could simply send us a sample of a mattress you are interested in, and we will recreate it. Moreover, we provide various additional services that have closely to do with mattress manufacturing, namely we offer raw mattress materials such as fabrics, felt, foam, springs, cocofiber etc. as well as quilting services.

Creating a perfect mattress

In order to perfect outer design of mattress, we try to automate every possible aspect of manufacturing. Besides economical reason, automation of process reduces human errors and leads to more ideal and consistent outcome. Even such a simple at a first glance task like foam cutting for example is done using complex commercial machinery dedicated to that purpose, all for the same reason, production volume with uncompromising quality.